- Home

- >

- All Products

All Products

Paper

With a strong track record of our large number of services in Paper industry since 2006, today we have crossed the client of 100+ paper mills all over India with all the big guns in paper industry being served by us. We also provide services to various countries Alloy Spray Engineering being the first Indian company in thermal spraying services to[..]

GEM BID and RA InformationQuantity : 1 Paper Industry

Price : 1

View More

Chemical

The industry demands a well studied & sure solution for its surface wear problem. As surface wear in chemical & fertilizer industry is basically corrosion (surface wear due to chemical action) & not much of erosion. This enables us in providing our client of the specific industry the true surface wear solution, which does have better se[..]

GEM BID and RA InformationQuantity : 1 Chemical Industry

Price : 1

View More

HIGH VELOCITY OXY-FUEL (HVOF)

Our company PROCURED WORLD LATEST HVOF SYSTEM FROM TAFA - PRAXAIR Excellence Flame Velocity & Particle Velocity. FLAME TEMPERATURE DURING COATING around 3,000 °C and high bond strength 10,000 psi – HVOF is the latest thermal spray system which is getting wide acceptance worldwide because it finds diverse applications in a cross sectio[..]

GEM BID and RA InformationQuantity : 1 Schematic of HVOF Combustion Chamber

Price : 1

View More

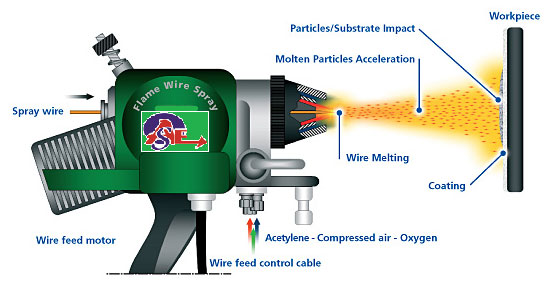

Flame Spraying

Flame spraying is a thermal spraying process that uses an oxy-fuel gas flame as a source of heat for melting the coating material. Compressed air is usually used for atomizing and propelling the material to the work piece. There are two variations: one uses metal in wire form and the other uses materials in powder form. The method of flame spraying[..]

GEM BID and RA InformationQuantity : 1 Schematic view of Flame Spray process gun

Price : 1

View More

Electric Arc Spray

Electric arc spraying is a thermal spraying process that uses an electric arc between two consumable electrodes of the surfacing materials as the heat source. A compressed gas atomizes and propels the molten material to the workpiece. The principle of this process is shown by figure. The two consumable electrode wires are fed by a wire feeder [..]

GEM BID and RA Information