Principles of Thermal Spraying

by : National Tenders

Quantity : 1 01

Price : 1

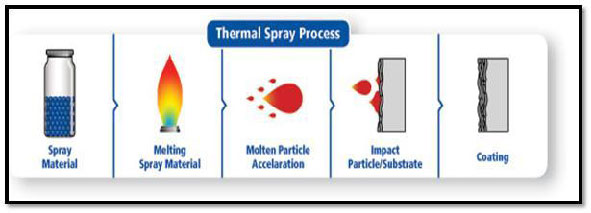

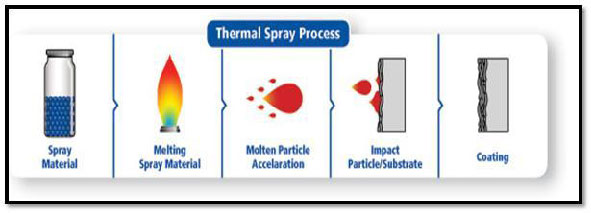

The Basics : All thermal spraying processes rely on the same principle of heating a feed stock, (Powder or Wire) and accelerating it to a high velocity and then allowing the particles to strike the substrate. The particles will then deform and freeze onto the substrate. The coating is formed when millions of particles are deposited on top of each other. These particles are bonded by the substrate by either mechanical or metallurgical bonding.

Figure : Basic steps of thermal spray process The Process :

· The first step of any coating process is surface activation. This is done by cleaning and grit blasting the surface to be coated. Masking techniques are normally adopted for components that only need specific areas coated.

· The second step is to melt the material; this is done by introducing the feed stock material into the hot gas stream. The hot gas stream is produced by either chemical reaction (Combustion) or by physical reaction (Plasma).

· Thirdly the particles are then accelerated to the substrate by the gas stream and deform on impact to form a coating.

· Finally the coatings are inspected and assessed for quality by either mechanical or microstructure evaluation.

Thermal spraying can provide thick coatings (approx. thickness range is 20 micrometers to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals, alloys, ceramics and composites. They are fed in powder or wire form, heated to a molten or semi molten state and accelerated towards substrates in the form of micrometer-size particles. Combustion or electrical arc discharge is usually used as the source of energy for thermal spraying. Resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significantly, allowing the coating of flammable substances.